Views: 90

Posted on: 2025-08-08 05:16:50

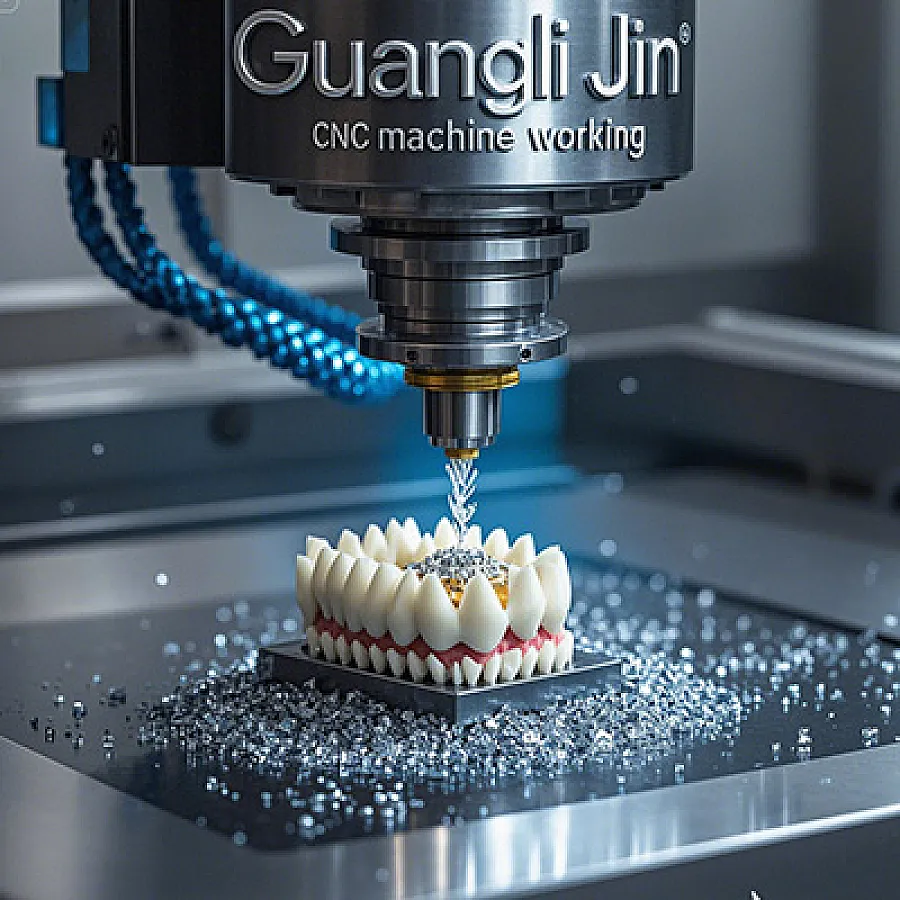

How to Choose the Right 5 Axis CNC Router System?

Selecting the perfect 5 axis CNC router involves balancing multiple technical and operational factors. With options ranging from $50,000 to $500,000+, manufacturers often struggle to identify the optimal solution.

Our team learned this lesson in 2024 when we helped an aerospace supplier upgrade their equipment. The right choice reduced their aluminum part cycle time by 40% while improving surface finish to Ra 0.6µm.

| Feature | Entry-Level | Industrial-Grade |

|---|---|---|

| Positioning Accuracy | ±0.003" | ±0.0005" |

| Spindle Power | 10-15 HP | 20-40 HP |

| Max RPM | 18,000 | 24,000-30,000 |

| Duty Cycle | 60% | 90%+ |

Critical errors to avoid:

According to Modern Machine Shop's 2024 survey:

Interestingly, 78% of successful implementations involved thorough pre-purchase testing of actual production parts.

Choosing multi-axis routers requires evaluating rotary table accuracy and spindle performance. For optimal results, consider control system compatibility and work envelope size.

Evaluation Criteria:

Verify machine specificationsQ: What's the typical lifespan of a 5 axis CNC router?

A: 7-10 years with proper maintenance and timely upgrades.

Q: How much floor space does a 5-axis router require?

A: Typically 150-400 sq ft, depending on work envelope.

Q: What training is needed for 5-axis operation?

A: Both CAD/CAM programming and machine operation training are essential.