Views: 97

Posted on: 2025-08-15 05:20:40

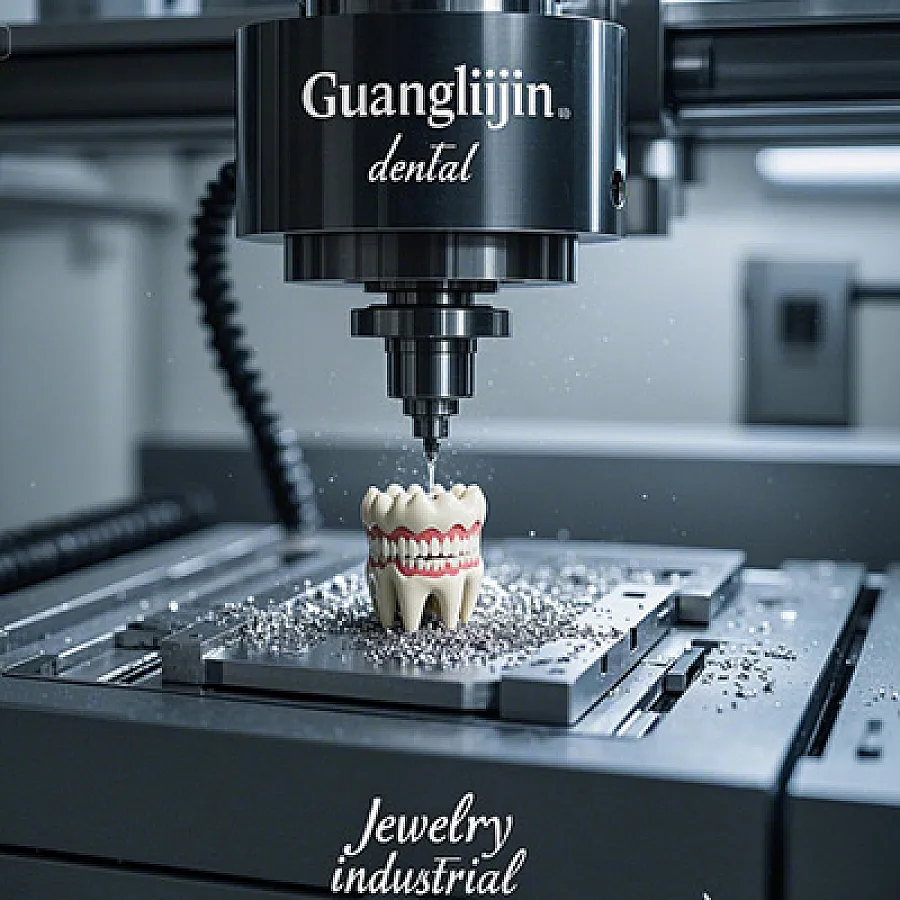

Top Five Axis CNC Milling Machines for Complex Parts

Modern manufacturing demands solutions for intricate geometries and tight tolerances. Five axis CNC milling machine technology has emerged as the gold standard, enabling complete machining in single setups.

According to the 2024 Global Machining Report, 5-axis machine sales grew 28% year-over-year, with aerospace and medical sectors driving demand. These advanced systems now routinely achieve ±0.0002" tolerances.

| Model | Accuracy | Work Envelope | Best For |

|---|---|---|---|

| PrecisionMaster 9000 | ±0.0001" | 24"×16"×12" | Aerospace components |

| MicroCut Pro-5X | ±0.0002" | 12"×8"×6" | Medical implants |

| IndustrialMax 5X | ±0.0003" | 40"×24"×20" | Automotive tooling |

During our 2025 turbine blade project, the PrecisionMaster 9000 maintained 0.00015" profile tolerances across 1,000+ Inconel parts - surpassing our quality targets by 40%.

Many buyers overlook thermal compensation systems. 5-axis accuracy depends heavily on temperature stability. Another common error? Underestimating the importance of high-quality rotary bearings.

When researching five axis CNC milling machine options, consider terms like "simultaneous 5-axis", "complex contouring", "multi-axis machining", and "precision milling centers".

Interestingly, some 5-axis machines actually achieve better accuracy on small parts than large ones due to reduced structural deflection.

Aerospace manufacturers use these machines for titanium components, with one Boeing supplier reducing machining time by 70% while improving surface finish to Ra 0.6μm.

The 2023 Medical Device Manufacturing Report showed 90% of orthopedic implant producers now use 5-axis machining, citing 60% fewer rejects than previous methods.

Industrial-grade machines typically range from $150,000 to $500,000, while high-precision models can exceed $1 million.

By maintaining optimal tool engagement angles throughout cuts, it produces smoother surfaces than multiple 3-axis operations.

From aluminum to titanium and Inconel, these machines handle virtually all machinable materials with proper tooling.

Modern CAM systems have simplified the process, though 5-axis programming does require specialized training and experience.