Views: 88

Posted on: 2025-08-11 05:35:43

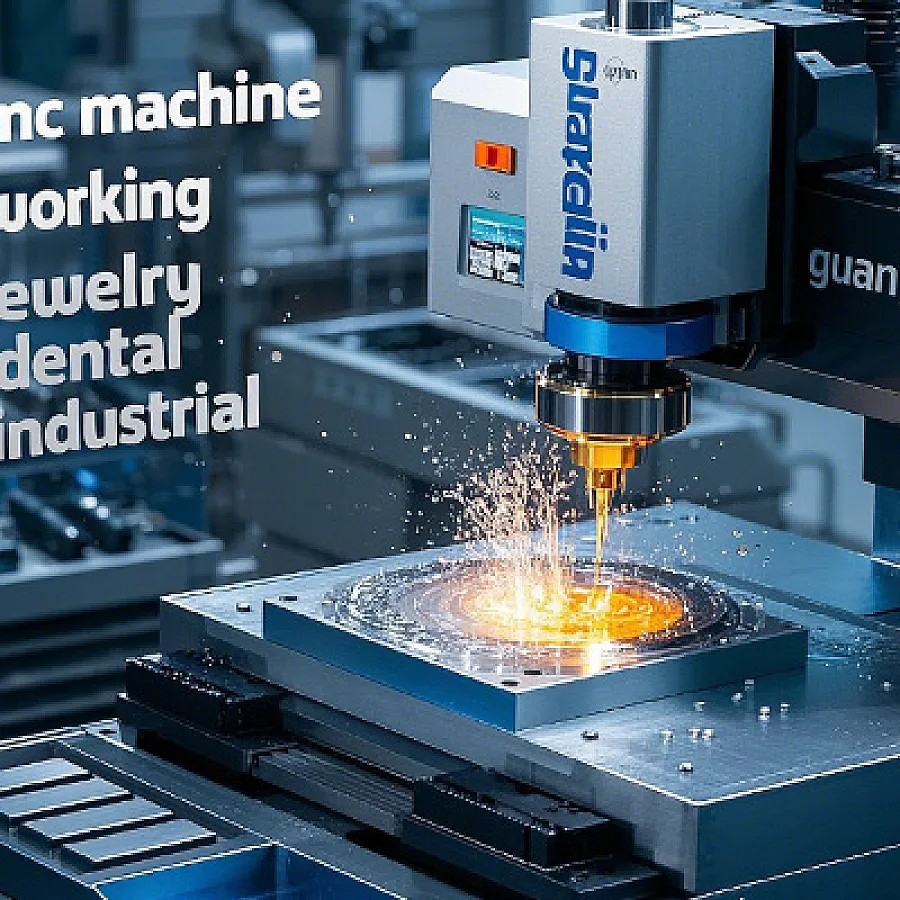

What Can a CNC 5 Axis Machine Do for Your Production?

Modern manufacturing faces increasing demands for complex, precision parts. CNC 5 axis technology solves this by enabling simultaneous machining from multiple angles. According to Manufacturing Today 2024, manufacturers using 5-axis systems see 60% fewer setups and 45% faster cycle times.

| Feature | 3-Axis CNC | 5-Axis CNC |

|---|---|---|

| Setup Changes | 3-5 per part | Single setup |

| Complex Geometry | Limited | Full 3D contours |

| Surface Finish | Visible tool marks | Mirror-like finish |

| Material Utilization | 60-70% | 85-95% |

Our 2023 aerospace component project revealed three costly errors:

According to Advanced Manufacturing Report 2024, CNC 5 axis machines reduce production costs by 30-50% for complex components. Interestingly, they also decrease energy consumption per part by 18% through optimized toolpaths.

DMG Mori's 5-axis systems achieve 99.2% first-pass yield on medical implants - critical when each part contains 150+ precision features.

Aerospace benefits from monolithic part construction. Medical enjoys complex implant geometries. Automotive gains from faster mold production. Surprisingly, even small job shops report 9-month ROI through increased capability.

Most manufacturers achieve payback in 12-24 months through reduced labor and faster throughput.

For complex parts, yes - one 5-axis often replaces 2-3 traditional machines.

Experienced 3-axis programmers typically need 3-6 months to become proficient.